As a construction manager or heavy equipment operator, choosing which parts to purchase in the heavy machinery industry can be challenging. When choosing between aftermarket and original equipment manufacturer (OEM) parts, a crucial decision is often prominent. Every decision has its benefits, and understanding which one to choose will have a significant impact on the performance and lifespan of the device. In this blog article, we will explore considerations when choosing aftermarket and OEM parts.

Understand after-sales accessories

They are produced by companies other than the original manufacturer. These alternatives are usually more affordable, have a wider range of options, and are suitable for those with tight budgets or requiring immediate replacement of parts. When choosing aftermarket parts, there are some key considerations:

1.Cost effectiveness – aftermarket parts are usually more affordable than OEM parts, making them an excellent choice for projects or budget constrained projects.

2.Diversity and availability – aftermarket partstypically have a wider range and offer more options. They are also easy to obtain, which can reduce downtime during maintenance.

3.Quality precautions – Although many aftermarket parts meet or even exceed OEM specifications, the quality may vary. Choosing a reputable supplier is crucial for ensuring reliability.

The World of OEM Parts

OEM parts are manufactured by original equipment brands to ensure they match the specifications of the original components. Here are some precautions when selecting OEM parts:

1.Ensure compatibility – As OEM parts come from original equipment manufacturers, these parts are specifically designed for machines, providing a sense of compatibility and safety.

2.Consistent Quality – Maintaining a consistent level of quality for OEM parts is crucial for heavy-duty machinery operating under harsh conditions.

3.Long term investment – Although the upfront cost of OEM parts may be higher, ensuring quality and compatibility can prolong the service life of your equipment and lower maintenance costs.

Making the right choice

Your choice between aftermarket and OEM parts should consider the equipment’s lifespan, application, budget, and operational criticality. Here are guidelines to help you make decisions:

1.Equipment lifespan and application – For older machines or less critical applications, aftermarket parts may be a cost-effective choice. However, for newer equipment or equipment in critical operation, the reliability of OEM parts may be more advantageous.

2.Budget considerations – review your budget constraints and weigh them based on the specific needs of your equipment. Determine whether the initial savings in the after-sales market exceed potential long-term costs.

3.Supplier reputation – Whether choosing the aftermarket or OEM, the reputation of the supplier is crucial. Finding suitable suppliers that meet industry standards and provide reliable, high-quality products is crucial.

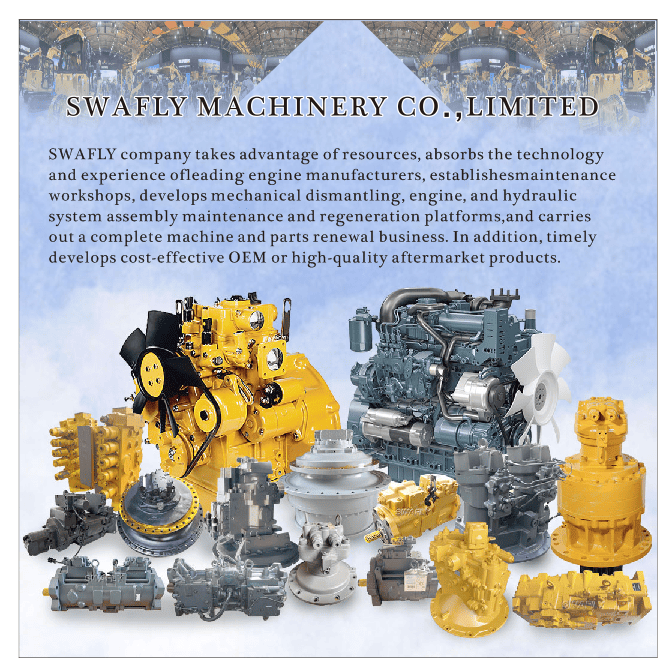

Choosing between aftermarket and OEM parts is a balancing act. The choice can be attributed to various factors, including budget, equipment lifespan, and operational criticality. We understand the importance of this decision at SWAFLY MACHINERY CO.LTD. Our commitment is to guide you through these choices and provide various after-sales and OEM heavy-duty machinery parts. Strive to find the parts you need? Visit the SWAFLY website to browse available excavator parts inventory, view the equipment currently being dismantled, and immediately request a free quote.